The problem of waste batteries is getting worse every year. Improper disposal of batteries can be detrimental to the environment.

Portable batteries are one of the most dangerous items of waste. Batteries contain many hazardous substances and must be properly sorted to meet recycling standards.

“…the cost of fires to the waste and recycling operators and to the fire professionals who are forced to fight these fires is more than US$1.2 billion annually” (taken from waste360.com)

Poor sorting of battery purity can lead to emergency situations at processing plants, fraction contamination and property degradation.

Read more from linevsystems.com

Datasheet

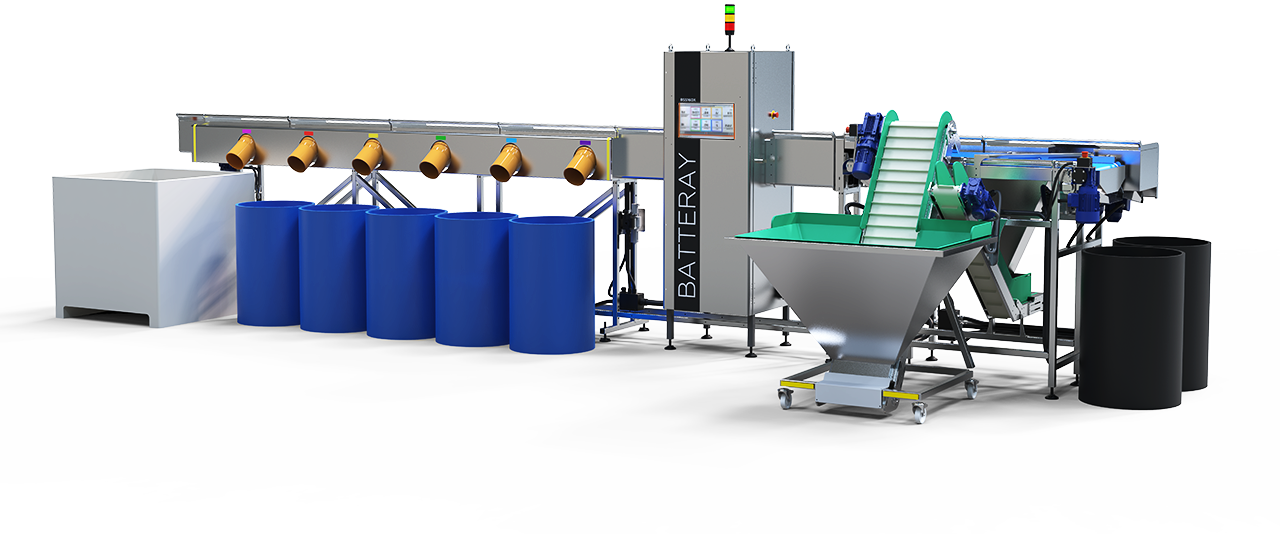

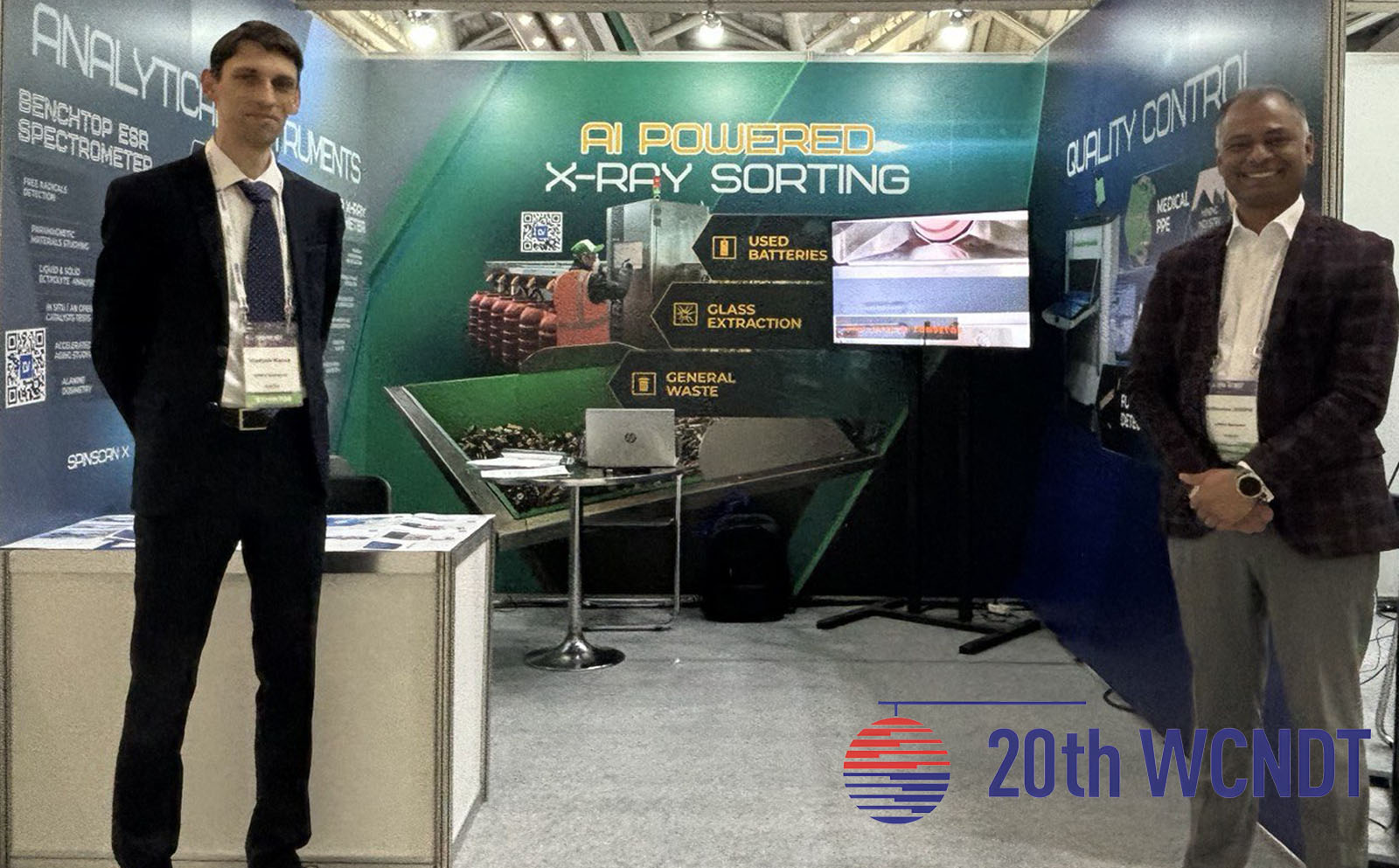

Since 2018, our team has been investigating the possibility of using the X-ray technology to solve the problem of identification and sorting of different types of waste batteries. As a result we developed and manufactured BATTERAY – an X-ray device that sorts portable waste batteries.

This X-ray battery testing and classification system is a powerful and versatile tool for identifying battery types and sorting them accordingly.

Key Factors

- BATTERAY is a unique technology unmatched on the market.

- The influence of the upper layer of the battery is eliminated. The system correctly recognizes the battery type even if the label or marking is missing or the battery is counterfeit.

- BATTERAY recognizes the type of batteries by scanning them with X-rays, which is safe for the operator.

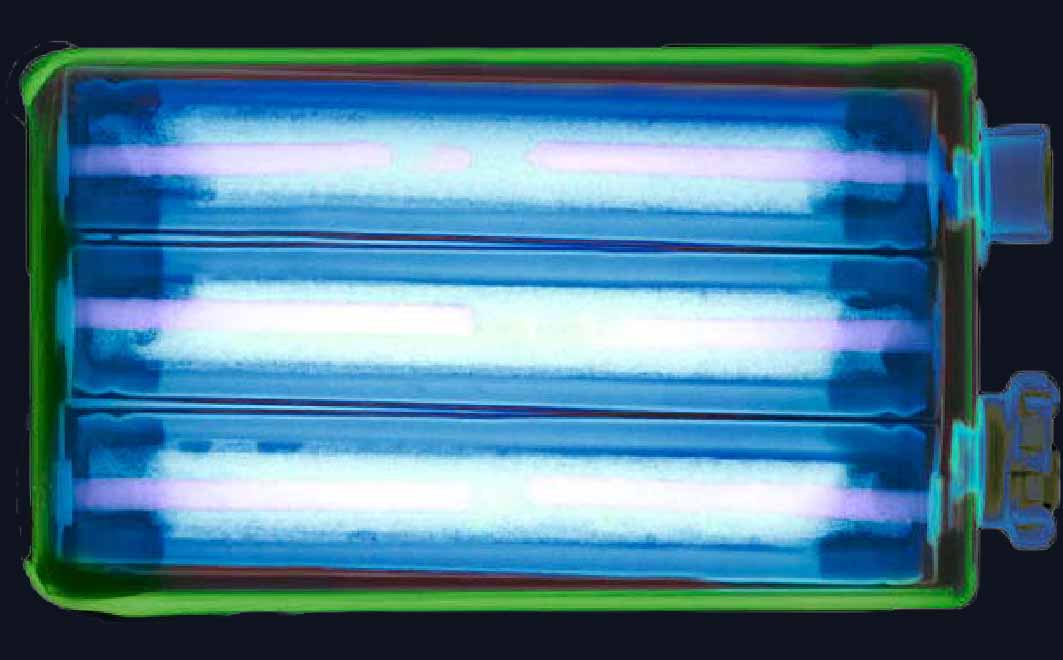

One of the main features of BATTERAY is its advanced imaging technology that can achieve excellent results by visualizing the internal structure of the battery. The system’s advanced image processing algorithms can identify even unmarked batteries, avoiding costly breakdowns and safety risks.

BATTERAY X-ray battery testing and sorting system is designed for ease of use and flexibility, with customizable test protocols and an intuitive user interface that streamlines the process. The system’s modular design and flexible configuration options also make it easy to adapt to different battery types, equipment and test requirements, providing a versatile solution for a wide range of applications.

Software Features

- Standard sorting (default sort map)

- Sorting with customer-added batteries (default sort map + customer base) – the user can add previously unrecognized batteries to the database

- Programs for adding batteries containing non-standard sizes from AAAA to 21700 are not included in the pre-trained classification cards

Sorting battery groups:

- Zn-Carbon

- Alkaline

- Li-Ion

- Li-Primary (Li-SOCl2, Li-MnO2, Li-FeS2)

- Nickel-Cadmium (NiCd)

- Nickel-Metal hydride (NiMH)

Sort map

| ZN | ALK | NiCd/MH | NiCd | NiMH | Primary Li | Li-Ion | |

| AAAA | + | + | + | + | + | ||

| AAA | + | + | + | + | + | + | + |

| AA | + | + | + | + | + | + | + |

| C | + | + | + | + | |||

| D | + | + | + | + | + | + | |

| 6F22 (9V) | + | + | + | + | |||

| 21700 | + | ||||||

| 18650 | + | ||||||

| A23 | + | ||||||

| A27 | + | ||||||

| CR2 | |||||||

| 16340 (R123) | + | + | |||||

| 1/2 АА | + |

Key features

Damaged Batteries Detection

Damaged, corroded and counterfeit batteries friendly

Artificial Intelligence

Battery sorting using AI-powered X-ray technology

High productivity

The conveyor speed enables sorting with a productivity of 350-400 kg per hour.

High purity of sorting

Purity of sorting for Alkaline/ZnC–99,5%

Popular types of batteries

A standard comprehensive coverage map including the most common battery types and sizes

Proprietary technology

Patented BATTERAY is a unique LINEV Systems technology that is unmatched on the market.

Damaged Batteries Detection

Damaged, corroded and counterfeit batteries friendly

Artificial Intelligence

Battery sorting using AI-powered X-ray technology

High productivity

The conveyor speed enables sorting with a productivity of 350-400 kg per hour.

High purity of sorting

Purity of sorting for Alkaline/ZnC–99,5%

Popular types of batteries

A standard comprehensive coverage map including the most common battery types and sizes

Proprietary technology

Patented BATTERAY is a unique LINEV Systems technology that is unmatched on the market.

The conveyor speed enables the sorting process with a productivity of over 350 kg/h

Alkaline/ZnC grade purity – 99.5% meets recycler requirements.

A standard and comprehensive coverage map including the most common battery types and sizes

Product Videos

Technical data

X-ray source

| X-ray emission | Complies with the standard: 1 μSv/h at any point at a distance of 10 cm from the device. Typical value of our system less than 0.3 μSv |

| X-ray protection | Full operator protection |

Loading

| Loading hopper capacity, up to | 350 kg |

| Loading hopper volume | 250 L |

| Conveyor speed | 1.0 m/s |

| Productivity of pure fractions | up to 25000 batteries/hour |

| Pneumatic | no less than 8 bar, 500 SLPM |

| Throughput capacity | 350-400 kg/hour |

Dimensions

| Overall dimensions (maximum) | ||

|---|---|---|

| Lenght | 7960 mm | |

| Width | 2690 mm | |

| Height | 2400 mm |

| Layout | 15000 x 8000 mm |

|---|

| Weight (maximum) | 2400 kg |

|---|

Purity

| Zinc-carbon, alkaline | 99,5 % |

| All groups | >95 % |

X-ray source

| X-ray emission | Complies with the standard: 1 μSv/h at any point at a distance of 10 cm from the device. Typical value of our system less than 0.3 μSv |

| X-ray protection | Full operator protection |

Loading

| Loading hopper capacity, up to | 772 lbs |

| Loading hopper volume | 66 gal |

| Conveyor speed | 3.28 ft/s |

| Productivity of pure fractions | up to 25000 batteries/hour |

| Pneumatic | no less than 116 psi, 500 SLPM |

| Throughput capacity | 772-882 lbs/hour |

Dimensions

| Overall dimensions (maximum) | ||

|---|---|---|

| Length | 26.1 ft | |

| Width | 8.8 ft | |

| Height | 7.9 ft |

| Layout | 49.2 x 26.2 ft |

|---|

| Weight (maximum) | 5291 lbs |

|---|

Sorting purity

| Zinc-carbon, alkaline | 99,5 % |

| All groups | >95 % |

Feedbacks and related links

Customer Reviews & Installation Videos

There are many different types of batteries and rechargeable batteries on the market today. They all belong to the hazardous household solid waste category, as they contain varying concentrations of highly toxic heavy metals such as mercury, cadmium, and lead, depending on the type of electrochemical cell. According to expert literature, used batteries account for up to 40% of all pollutants entering the environment through household waste.

There are over 200 types of batteries and accumulators on the market (excluding various manufacturers) depending on the size, shape and composition of the electrolyte. Sorting these various objects requires an efficient logical sorting scheme.

Industrial applications of optical methods and sorting methods based on the specific peculiarities of batteries are theoretically well characterized and thus less accurate, but in practice may be false or non-detectable.

Since 2018, the LINEV Systems team has explored the fundamental potential of solving the problem of identifying and sorting different types of waste batteries using X-ray technology, as well as the selection of key components and the optimal mode. Many studies have been conducted to prove the need for this technology.

The fastest way to hear back from us is completing the contact form below. Our expert team will get back to you as soon as possible.